Ford Stroker Tech 347, 427w

On virtually all engines, the intake valve stays open after the point where the piston starts up on the compression stroke. Until the intake valve actually closes, compression is not occurring and the true compression stroke does not start until it does. Because the cylinder volume is reduced, so is the dynamic compression ratio. The later valve closing takes advantage of air velocity at higher engine speeds to help fill the cylinder. At low speeds, yes, that reduces the effective compression ratio, but at higher speeds the increased volume of air more than makes up for it.

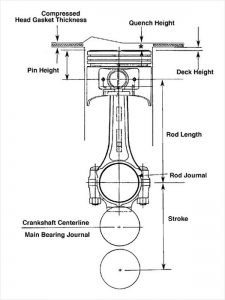

When we did a trial assembly of the stroker parts in the stock block, our deck clearance was 0.045 inch. We ended up removing 0.020 inch from the deck. Different aftermarket pistons have different pin heights and therefore different deck heights. Installing one piston and measuring your deck clearance to calculate the final compression ratio could save you heartaches later.

Decking the block can be an important step with a stroker. It has to do with quench height. The best idea is to deck the block for a zero deck height and a 0.040-inch quench height, but you must increase the combustion chamber size, either by enlarging the combustion chamber in the head or increasing the piston dish size. Don’t do it unless you have calculated the effects and have the right parts. Here, 0.020 inch is being removed from our block.

We were shooting for an SCR at or slightly below 10 to 1. We measured the volume of the combustion chambers in the head. You can measure the dish separately, but in the cylinder, you also see the ring land volume (generally about 1.1 to 1.3 cc). We used the thinner of the two commonly available head gaskets, and after taking about 0.020 inch off the deck for a clearance of 0.025 inch.

The big question now is, “Why does this matter?” The bottom line is that the DCR is a major factor in whether you can run on regular, midgrade, premium, or race fuel, and not ping. Also, if the DCR is too low, you will lose bottom-end torque.

The next step is for you to determine what parts will give you the right SCR to match. If you can’t find the right mix of parts for the job, the easiest route is usually a longer-duration cam.

You can get a rough idea of what your compressed dimension will be by measuring the thickness of the gasket body (not the flame ring around the bore or sealing strips imprinted on the body) and deduct about 0.005 inch. This applies to the gaskets advertised as “permanent torque” or “no-retorque.” Cheaper gaskets that require retorquing can compress two to three times that much and are less predictable. Bottom line, you cannot say with certainty that X gasket has Y thickness unless it’s a performance gasket that has a listed specification.

Quench is the “Great Equalizer” when it comes to a high compression ratio. The quench area is the area between the highest flat spot on the piston and the lowest part of the roof of the combustion chamber. Less quench distance induces more turbulence in the combustion, which promotes better fuel mixing and fewer hot spots-all of which reduce pinging. Many experts think that 0.040 to 0.045 inch of quench is ideal,

To Get Deck Height (DH)

deck height = block height* – rod length – piston pin height – 1/2 stroke

To Get Compression Ratio (CR)

CR = total cylinder volume combustion chamber volume

To Get Combustion Chamber Volume (CCV)

CCV = cyl head volume + head gasket volume + deck clearance volume + piston dish volume

To Get Cylinder Volume (CV), Deck Clearance Volume or Head Gasket Volume

CV = 0.7853942 x bore2 x stroke

Note: For head gasket, used compressed distance.

To Get Quench Height (QH)

QH = deck height + head gasket compressed distance

*Block height = Distance from crankshaft centerline to block deck