Frequently Asked Questions

Ahsan Bilal2023-12-10T09:31:54+00:00This is one of the most common questions our technicians answer. We will ask you a list of questions that will help point you in the right direction. For example: A. What is your car or truck being used for? B. How often do you drive your vehicle? C. Is idle quality important to you? Do you have a budget your working with or don’t want to exceed? These are just a few of the questions we will address to make your buying decision the proper one for you. Perhaps you have an early Mustang with a 5.0 liter that has high mileage and is tired. You are looking for something you can use as a daily driver with good low end torque plus midrange horsepower for highway use and your budget for a complete turnkey engine is under $7,500.00.

OFFER SEVERAL VARIATIONS OF THE 302:

- 302 / 200 HP Stock

- 302 / 300 HP Stage 1 – One step up from stock engine

- 302 / 350 HP Stage 2 Two steps up from Stock engine

- 347 / 425 HP Stroker Stage 3 Four steps up from Stock engine

We would recommend the 302 / 350 HP version as being a good overall fit for this customer. It is worth mentioning though that all of our engines are very streetable. Just that some are more aggressive than others. How much Horsepower? We all can get caught up with Horsepower bragging rights. What we want and need are two different things. Take for instance a Cobra Replica. The Weight to Horsepower Ratio of these car’s is incredible, better than a Ferrari, Porsche and Lamborghini at a fraction of the price. Something with a classic muscle car sound, street friendly, tear a little rubber, handles nicely and still gets decent gas mileage, is accomplished with an engine in the 350-400 Horsepower Range. Step up to a little more aggressive street performance engine then our stroker Small block Engine packages in the 400-450 HP are great too, anyone of these motors will get the adrenaline going. Quick revving, a little more rumble, smoke the tires and gobs of power! Wanna run with the big boys then take a look at our Street / Strip Windsor packages. 500+HP 427w have crazy power. You can roast your tires on demand. Surprising still street friendly, definitely more attitude, more rumble, scary fast and more conducive for a street / strip use.

We have categorized our engine packages based upon vehicle type and performance levels. two most popular setups for the Ford Mustangs and the Cobra has been the 302 and 351w Based engines. There are of course the Big Block engines – 390 and 427FE’s. The 5.0 Coyote litre engine is now in the mix too. The reason for the 302 and 351w being as still most popular is they are good happy medium. Lightweight, nice power gains. run cool,. Putting a Ford into a Ford is still important to the purist, most of the chassis are set to accommodate the small block Fords too. The FE engines are still popular for some manufacturers like ERA and Kirkham. These engines are bigger, heavier and create more heat. The 5.0 Coyote is newer technology but a tight fit for restomods and some retrofitting involved.

If you have any ambitions to supercharge, turbocharge , running nitrous or road racing then notify us. Some upgrades to the internals like gaskets, compression, induction can be upgraded. How much Customizing is Allowed? Henry Ford was famous for the statement, “You can get any color so as it’s Black”. He was a smart man especially when working with economies of scale. The internal recipes of our engines we prefer to leave alone. The parts work in harmony and sometimes changing something throws off the equilibrium, but this doesn’t mean were not flexible. In regards to the Cosmetics we offer some different options. The standard engine color is the traditional Ford Blue. Black Blue or Red is an option. Ignition wire colors are available in Blue, Black, Red and Yellow, standard color being yellow. Polished options available too.

You get when you get. Just kidding. Some of our hotter selling engines we try to inventory to ship within 4 weeks for delivery. Some other engine / tranny combos that are more involved allow in the areas of 6-8 weeks.

Most of the restomod cars and Cobras are setup for a 5 Speed Transmission, so we will concentrate on this. There are a 6 Speed Manual Transmissions that are becoming more popular but sometimes require more retrofitting. Overall we recommend going with either a T5 or Tremec TKO series trans. They fit the best, have a 5th gear overdrive gear and are strong enough to handle some pretty big horsepower. In general the T5z Trans. is is sufficient for an engine up towards the 350-400HP range. Beyond this the TKO0-600 Trans. has a generous torque capacity of 600lbs. We do sell engine / tranny packages as an option to our customers for the convenience of one stop shopping. We’re not a Transmission dealer and don’t promise to have the lowest prices but from a convenience standpoint may be a good fit for you.

Traditionally we’ve sold a lot more carbureted setups than EFI but it is clearly evolving. For a very clean and traditional appearance, minimal wiring , installation time, and cost A Carbureted engine is a great way of going. We setup the fuel mixtures, idle, timing and tuning. In the past fuel injection hookup and tuning was difficult , this has changed as of recently. TD Performance offers a plug and play Fuel Injected Sniper and Sniper EFI Engine. It has the appearance of a retro look Carbureted engine but is definitely not carburetion. The new Fast EFI has taken a quantum leap in technology for aftermarket fuel injection systems. It is the easiest to install of any full featured system, The features the Engine Management System (EMS) mounted directly onto the throttle body thereby eliminating 80% of the necessary wiring harness. The throttle body assembly includes the EMS, throttle position sensor, MAP sensor, idle air control, and four 62lb. /hr. port style injectors. The linkage on the side of the unit is identical to a Holley 4-barrel and the throttle body has overall dimensions that are the same as a 4150 style Holley. We install a standard Air Cleaner on top. Despite the compact size of the EMS, it is still laptop programmable but for most vehicles the standard program is suitable. The EMS is self-learning which you can start the car up after installation, drive it around for 20 or 30 minutes and it dials itself in to the perfect tune. SEE OUR COMPLETE EFI ENGINE PACKAGES. This system will run approx. $2,000 more than our carbureted engines. So the question is which way to go Fuel injection or Carbureted? We try to sum it up like this: If you plan on driving your car once in a while, show and go, or on a occasional cruise than a Carbureted engine will work great for you. If you put a lot of miles on your car, drive in different altitudes, want a smoother idle, emissions is a concern and drive a lot in colder climates than Fuel injection is probably a better way of going. You can get 10-15% better gas mileage. This will pay the difference in initial cost. TD

There is plenty of miscellaneous items to make your car Road Worthy, Trying to Piece Meal together an Engine shouldn’t be one of them. Lets focus on the popular Replica kit cars what’s left are Wheels, paint and Transmission items needed to finish once you purchase the Complete Engine from us. Our engines come complete with all the accessories, pulleys back to rear flywheel. We provide the engine with a DVD of your engine running, instructions on where the fuel mixtures, ignition timing ect have been set. Stickers and labels on some of the installation basics. Most of our engines are shipped with oil as well. A few items that are needed water and oil temp temp switches and a throttle cable bracket. Most kit suppliers will furnish the headers, engine mounts, wiring harness and sensors to complete the job. We don’t supply a starter with the Ford engines mainly because it doesn’t mount on until the transmission bellhousing is bolted on first. We do offer a mini high torque starter as option, or when you purchase one of our Engine / Transmission packages. We provide some instructions with our motors to give you some indication as well.

In a perfect world we like to think things can be completed in a month or two. But Going at it solo and on a part time / weekend project can take many moons to complete as many of you can attest to. So to answer the question about how long the engine can sit in storage, the answer is for a long time. We have customers need to get the engine ahead of time to mock things up and then pull the engine out again to put aside. We have a lot of heavy duty lubricant on the bearings and load areas for the first start up. If an engine sits for over 6 months then fogging the upper cylinders with some lubricant like CRC or WD-40 will do some good. We don’t recommend pulling the distributor and priming the oil pump. We do this ahead time, plus it defeats the purpose of purchasing a Turnkey Engine.

302

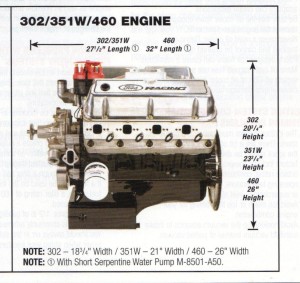

The 5.0 litre Engine has been a venerable part of Mustang & Cobra Replica Industry for 25+years. Lightweight, Plentiful, can be upgraded to achievable impressive Horsepower, fits very easily in chassis, lightweight and overall pretty reliable. Carbureted or Fuel Injected. For someone who wants to use their car as a cruiser with some extra kick we would suggest going with the 302 / 350 HP or 375 HP engine package. To increase the torque capacity of the motor, stroking it to achieve 331 or 347 cubic inches is the way to go. The “stroker” is impressive with 0-100mph times being very fast! Usually when trying to attain horsepower beyond 425+ we would suggest going with the 351w based motor. The 351w has thicker webbing, larger main caps and Head bolts and doesn’t have to work as hard to generate Torque.

351w

The 5.8 litre engine is a great way of going for a number reasons. This motor shares the same engine mount and bellhousing bolt pattern as the 302. It’s a couple of inches wider than the 302 so the headers are different otherwise still makes for a great fit. It weighs only 70lbs. more than the 302 which isn’t anything significant. Apples to Apples to a 302 it’s a capable of handling more Torque and Horses being that the block is more reinforced. Our 351w / 400 Horsepower engine is probably the best bang for the buck we offer. The 351w Stroker combinations we offer – 393w, 408w, 418w and the 427w deliver up to 550HP. This is just amazing output from a Naturally aspirated small block V8!! So for anyone who wants get a mean sounding engine with the benefits of the small block this is the way to go!!

460 Big Block Engine

The Big Block Ford engine without a doubt delivers huge torque at low RPMs and can sound pretty mean. From a practicality standpoint we don’t recommend it though. Weighs a lot more than a small block, poor fuel economy, Tighter fit for engine and Trans. tunnel, more cost, car is harder to handle and steer. The small block ford these days can deliver some phenomenal power without needing to go as a Big Block.

5.0 Coyote Motor

The 4.6 Mod engine has been out for quite a while but the Coyote motor is conducive for restomods. Will fit early Muscle cars but a Much tighter fit with more retrofitting of the chassis.

This is a concern for people wanting more power but are worried that their factory tranny is not up to the job. Most of our engines as are not for all out racing. That is why we usually say that factory transmissions will bolt up and work fine for cruising . While the engine is pulled out of your vehicle it never hurts to freshen things up with a shift kit and / or slightly higher stall speed converter. As you get more and more radical with an engine it’s probably worthwhile to upgrade your transmission. As with anything the weakest link is always going to go first. So lets say if you have an original engine putting out 175 HP and you are moving up to a 400 + HP street beast. More than likely your Transmission needs to be upgraded. Different Gear Ratios can also have a huge affect on low end power.

This is a yes or no answer. Whenever your swapping out to a different or larger engine some questions that would need to be addressed.

- Will all your existing parts ex: Pulley, Brackets, Transmission, exhaust etc. switch over to the larger engine?

- Are you committed to spending the extra labor time and expense to making the transition work if it is not a direct bolt in swap?

- Will you see a significant gain in horsepower in making the change?

The good news is that there are some engines that can interchange very easily. One very popular upgrade our customers do with early mustangs having 289s or 302s is switch over to a 351w. This is pretty much a direct bolt in with the proper setup. Speak to our Sales Tech staff regarding swaps and they can give you some input.

When you purchase a turnkey engine from TD you will receive a fully dressed assembly. Here is a list of what most of our engines come with:

- Brand New Casting Aluminum Heads

- New Stainless Steel Undercut and Polished Intake & Exhaust Valves

- Hard exhaust valve seats for unleaded fuel

- Three Angle Competition Valve Job

- CNC Ported Matched Intake Runners

- Water pump

- Fuel Pump

- Fuel Lines

- Polished Baffled Valve Covers

- Breather and PCV valve

- Harmonic balancer

- Belt(s)

- Alternator brackets*

- 100 Amp Alternator*

- Electronic 1 wire Hookup Distributor

- 8 mm plug wires

- Champion spark plugs

- Timing cover

- Flywheel

- Chrome oil pan

- Underdrive Aluminum Pulleys*

*Note: Included with COBRA Kit package knows the pride our customers take in restoring their cars. Thats why our engine builders pay special attention to detailing the overall appearance of your motor. To insure quality and performance, each engine is test run for approximately 1 hour. During this time the cam is broken in, all valves are adjusted, the carburetor is adjusted and the ignition is timed. All systems are checked to be sure that there are no water, fuel or oil leaks under running conditions. When you receive your engine, it is ready to drop in place.

- Customers name, year, and type of vehicle

- Type of engine that we are supplying

- Style of tin ware, oil pan, timing cover, valve covers

- Brand and type of cylinder heads

- Valve size, spring size, combustion chamber size

- Compression ratio, and recommended octane

- Details about your PCV system, breather, and baffles

- Style and brand of your intake system

- Carburetor brand and CFM size

- Type of fuel pump, and fuel lines

- Details on how to wire your electric choke 1 wire

- Details on 1 wire distributor set up

- Specs for initial, centrifugal, and vacuum advance

- Details on flywheel and harmonic balancer

- Details on water pump, and coolant flow

- Recommended items that you should replace

- Hoses that should be replaced, and air burping

- Explanation of how cooling system works

- Live running of your engine for one half an hour

- Test for oil leaks

- Test for fuel leaks

- Test for vacuum leaks

- Test for proper temperature at all 4 corners of engine

- Test for oil pressure cold, hot, and @ 3000 RPM

- Adjust carb, distributor timing, choke, and fast idle

- Perform a cylinder balance test

- Review thermostat housing, and coolant flow

- Review type oil to use, and change recommendations

- Review alternator, pulleys, and wiring procedure

- Explain heat indicators attached to block

- Explain proper break in procedure

- Explanation of owners and mechanics responsibilities

- A contact person that you can call if problems occur

- A list of parts that you should use to maintain engine

- A sincere thank you for your business

When you purchase the complete engine package basically everything is there for you. Some of your responsibilities would include:

- Exhaust System

- Engine Mounts

- Transmission

- Front Pulley System (Some exceptions Apply)

- Aluminum Cylinder Heads can together to save as much as a 100 lbs.

- Have superior flow characteristics with larger intake & exhaust runners

- Hardened interlocking valve seats which allow use with Unleaded Fuel

- Stainless Steel 1 piece high swirl valves with 2 positive oil control seals

- Have Bronze guide inserts for better heat transfer

- Most are street legal and interchange with factory Cylinder Heads

This is definitely a common question. Changing over to Fuel Injection has become easier than ever before. We offer a Complete Plug n Play EFI engine that has a classic look with Modern day performance. All the Harnesses and Sensors included. The ECU is actually built into the Throttle Body. More Details on the Sniper EFI System Here. We test run the engine and make the adjustments necessary to get the engine up and running. What’s nice about it is there is a limited amount of hookup, everything is clearly labeled and you don’t need any special skills to get your engine up and running. Very similar hookup to a Carbureted engine as far as wiring goes. Fine adjustments with a Laptop can be done if you desire. The fuel line kit and fuel pump is also included. We have tested several other Fuel injection kits only to find much more complex setup time, restrictions on the camshaft, distributor and a lot more wiring and harnesses and fine tuning. The Fast EFI engines we offer will run approx. $2,000 more than our Carbureted engines so this is something that you need to weigh out. We suggest if you drive your vehicle only once in a while, maybe a weekend warrior then a Carbureted engine can work just fine for you and keep some cost down. The new Carbs are improved from the early years. But if you put a lot of miles on your car, drive in different climates, elevations, get a little better gas mileage or just stand out from the crowd then converting over to the Fast EFI engine can be a great way of going. Going over to a 87-93 Style Mustang Conversion EFI engine does require more time and expertise.

We have found that most of the Aftermarket Distributors make elaborate claims of significant Horsepower gains. This is simply not true. Unless your driving consistently over 6000 RPMs it can be a waste of money. The electronic distributor we provide with quality coil will deliver plenty of spark to give excellent throttle response.

This depends upon the use of the car or truck. For daily driven grocery getters or even weekend warriors, most engines kept under 5500 RPMs will hold up very well without making the investment into Forged pistons, Rods or the Steel Crankshaft. So for most street performance enthusiasts we usually go with a Hypereutectic piston which transfer heat easily and you can still very tight clearances. ARP quality rod bolts used for added insurance. The factory crankshaft will not break unless there is a cause and affect circumstance like for instance a balancer bolt left loose, a flywheel not installed correctly or main cap bolts improperly torqued in place. The aftermarket makes cast steel crankshafts which are around 25% stronger than original nodular cranks which we generally use for engines delivering up to 500 HP. When engines are running a supercharger or nitrous we would recommend going with Forged components. Engine Block Dimensions ENGINE LENGTH HEIGHT WEIGHT 302 27-1/2 Inches 20-3/4 Inches 18-3/4 Inches 351W 27-1/2 Inches 23-3/4 Inches 21 Inches

SHORT BLOCKS HAVE THE FOLLOWING INCLUDED.

Lower Block, Crankshaft, Connecting Rods, Pistons, Rings, Main Bearings, Rod Bearings, Cam Bearings, Camshaft and Timing Set occasionally. We prefer not to sell a short block mainly for the fact that it requires a lot of expertise to finish assembling. Proper Torque readings, Clearances, Alignment of Valve Train, Sealing, Matching of parts, Blueprinting etch.. The average shady tree mechanic will most likely encounter problems.

LONG BLOCK ENGINES HAVE THE FOLLOWING INCLUDED.

Lower Block, Crankshaft, Connecting Rods, Pistons, Rings, Main Bearings, Rod Bearings, Cam Bearings, Camshaft and Timing Set, Lifters, Gaskets, Cylinder Heads, Valve Train, Oil pump and sump. This also can require many labor hours of cleaning, rebuilding and reassembling of components like your oil pan, timing chain cover, valve covers, induction system, electronics, pulleys etch back onto the engine.

Our Turn Key Engines Include The Following:

- NEW CARBURETOR

- NEW ALUMINUM INTAKE MANIFOLD

- NEW ELECTRONIC DISTRIBUTOR

- NEW SPARK PLUGS TORQUED AND GAPPED

- NEW 8 MM SILICONE IGNITION WIRES

- NEW IGNITION COIL

- NEW CHROME AIR CLEANER

- NEW VALVE COVERS

- NEW OIL PAN

- NEW TIMING COVER

- NEW HARMONIC BALANCER

- COMPLETE P.C.V SYSTEM

- GROMMETS AND BREATHER

- NEW OIL FILTER AND HOUSING

- NEW DIPSTICK AND TUBE

- NEW WATER PUMP

- THERMOSTAT AND HOUSING

- NEW FUEL PUMP

- NEW FUEL LINES

- HOT RUN TESTING OF ENGINE

- THE VALVES FULLY ADJUSTED

- DISTRIBUTOR TIMING ADJUSTED

- CARBURETOR BEEN ADJUSTED

- ENGINE HOT TESTED FOR LEAKS

- OIL PRESSURE TESTED COLD & HOT

- AUTOMATIC CHOKE ADJUSTED

- NEW AUTOMATIC FLYWHEEL INCLUDED

- INSTALLATION VIDEO INCLUDED

- VIDEO OF YOUR ENGINE RUNNING

The objective of this article is to distinguish the differences between the Ford Windsor, Cleveland, FE, 351M/400 and the Big Block . For starters the 289 was produced from ’63-’68 and is almost identical to the 302 except for the stroke and camshaft which is either Mechanical or Hydraulic. A 289 has a 4.00 x 2.870 Bore and Stroke while the 302 has 4.00x 3.00. The 302 manufactured from ’85 and up has roller camshaft which we use exclusively. The 302 is more readily available, has better internal parts and can generate more power for less money! We offer Horsepower ranges of 275HP, 350HP, 370HP and up to 425HP all on pump Gas. The 351 Windsor is the biggest of the small block Ford engines. It has a Bore and Stroke of 4.00x.3.50. It was made at the Windsor, Ontario plant – which of course giving it’s name. The 351w is a beefier block than the 302/289 but has the same bore spacing and bore diameter. The deck height is taller and the Main journals larger. The Windsor has been in production since ’69 and still in production. We offer a wide selection of the Windsor engines and different stroke combinations (393,408,418w and 427w) making this a true Street Beast! The 351 Cleveland is in a class by itself and entered the scene in 1970 until 1974. It has canted valves and multi-groove keepers, hydraulic cam, pedestal -mounted rocker arms that are retained with cap bolts. Two types of heads where made they were the 2V and 4V. The 2V heads have open chambers with rounded ports, while the 4V has quench combustion chambers with larger rounded intake and exhaust ports. A 351c Cobra-Jet appeared in ’71 with 4-bolt main caps. A 351C Boss also came out in ’71 with 4V type chamber head with pedestals machined to accept a 302 Boss type valve train and mechanical cam. In ’72 open chamber heads were used with a flat top piston and the name changed to 351C HO. Being that the Cleveland is over 30 years old, they are becoming a rare find and hard to find parts. For this reason we interchange it with the 351w which share the same bellhousing and engine mount patterns. The Exhaust manifolds, Front brackets and Pulleys do need to be changed out. TD Performance offers the complete CVF and March Performance Pulley kit as an option on a swap like this.

Windsor 351 V-8 Engine

The 351 Windsor’s radiator hose attaches to the radiator and connects directly to the front of the intake manifold via a water neck.

- Valve cover is held in place by 6 bolts.

- Radiator hose connects to water neck on the front of the intake manifold.

Cleveland 351 V-8 Engine

The 351 Cleveland’s radiator hose attaches to the radiator and connects directly into the front of the engine block. It makes a 90 bend from the radiator to the engine block.

- Valve cover is held in place by 8 bolts.

- Radiator hose is a 90 degree hose that connects directly to the top front of the engine block.

The 351m and 400 have the same bore spacing as the 302/351C/351W but a taller block for a longer stroke and rods. They were considered the next generation of the 351 Cleveland. They share the same cylinder head bolt pattern as the Clevelands but most of the external bolt ons were different. The 400 started production towards the mid 70’s where compression was dropped down to around 8 to 1 compression. This of course affected Horsepower numbers. They had the 460 big block bell housing pattern to use larger clutches for greater torque capacity, which is why some people opt to swap out to a 460 Big block. The exhaust bolt pattern, pulleys, accessories and Brackets are not the same though. The 351M was introduced after the 400 to fill production demand for a 351 size engine. They were not known for their big performance by enthusiasts but a good engine when setup properly for low end grunt torque. Another distinction between the 289/302/351w engines, they use a front Aluminum Timing Chain cover and water exits the intake manifold face of the cylinder head through the intake manifold to the radiator. The 351C/351M/400 engines use a flat tin front cover instead and the block extends out to cover the timing chain. The water exits the block face. The FE engines are the 352/360/390/427/428 engines and are different from all other Ford engines. The 390 is set up basically the same as the other engines but are balanced internally as oppossed to externally on the 428. Some of the 427 engines are overhead cam and are extremely powerful yet rare especially the side oiler versions. The 428 isn’t much different but isn’t an overhead cam plus a rare find. Engine Factory simplifies matters and offers the 390FE. It will interchange with either the 352,360 or even the 428. We provide this engine package with the Cobra Jet Aluminum Heads, these alone generate an awesome amount of torque. We also provide a Stroker version of this that comes to 426 cubic Inches. The last of the Ford engines are the Big Blocks 429/460. 429’s were available from ’68-’73 and named Cobra-Jet, Super Cobra-Jet, and Boss. Basically the 429 was a wedge engine with hydraulic cam, 2-bolt main caps, and 2V or 4V carbs. The 460 is a stroked 429. The CJ had a hotter cam, larger carb, bigger port heads and valves. The SCJ had 4 bolt mains mechanical cam, adjustable non-positive stop rocker arm studs, stamped rockers arms push rod guide plates. The pistons are forged aluminum . The Boss had aluminum heads and hemi combustion chambers. Engine Factory offers the 460 Big block with the Edelbrock Aluminum Cylinder Heads. Good for running on the street where more broad power band is needed. An easy to identify on the Fords is to count the number of retaining bolts on the valve covers. This should be the same for cars and trucks. 5 bolts = FE Block 6 bolts = 289/ 302/ 351Windsor 8 bolts = Cleveland / Modified

You can reference this as well:

2 bolts the engine is a: 239/256/272/292/312 (produced from 1954 to 1964) 5 bolts the engine is a: 332/352/360/361/390/391/406/410/427/428/ (FE engine) 6 bolts the engine is a: 221/260/289/302/351W 7 bolts the engine is a: 429/460 8 bolts the engine is a: 351C/351M/400

Can I get 400 Horsepower out of my Original 289 Ford Small Block?”

Squeezing a “legitimate” 400HP out of a little standard bore 289 means putting in some serious mods. The engine would need spin high to get 400HP which means cam, porting, heads, headers, flo and decent aspiration. Components like a steel crank; high end rods, carburetion, etc. preferred for a “legit” 400HP SB motor that will stay together . Here is a typical example…… Block prep (bake, tumble, magnaflux and chase all holes) – . Bore & Hone with torque plates – . Line Hone Block – Square Deck Block – . Custom oil galley mods (grind/drilling) – . Passage cleaning, plugs, paint – . Cam bearing install – . Balancing – . . per piece mallory (used 4) = . Intake Port Matching -. Short block assembly with spec sheet and cam shaft degreed – . Hot Run test Engine -.

OTHER PARTS:

Ported Heads – . Roller Rockers – . Lunati Rods – Steel Crank, pins, slugs, rings – . Cust. Roller Cam / S-Lifters/Pushrods – Blue Thunder 2×4 plus twin 750 holleys / linkage – Water pump – 160 HV Oil pump – 60 Billet timing Set – Heavy Duty Damper –

That’s $10,000+. in PARTS not including additional work to get up and running.

One of our 302 or 351w will be a more cost effective and efficient way of going. Your not dealing with a 40 year old block either. We utilize a Roller camshaft and Aluminum cylinder Heads which makes it lighter and faster. [/sws_ui_toggle] [sws_ui_toggle title=”What makes TD Global Performance different from the Mass Marketing Mail order Engine Companies?”

1. Mass Marketed Engines are available in one size fits all.

This certainly makes life easier for the distributor but not to the customer. After reading the fine print there are frequently a lot of modifications to the engine needed to fit your vehicle. For instance: Oil Pan, Oil Screen, Dipstick and tube, Flywheel, Water Pump, Fuel Pump, Harmonic Balancer, Valve Covers, Intake Manifold, Distributor, Thermostat housing etc. What“s the purpose of buying an assembled engine if you need to disassemble it and build it again? When you order we ask the right questions specific to your vehicle so the engine is setup right the first time!

2. Mass Marketed engine companies dont sell a truly Ready to run Engine.

Bear in mind they may come complete with the essentials but look at a typical list of parts needed to make it a truly Turnkey Ready engine: Carburetor or Fuel injection Kit (We provide the computer, Harness and sensors) Throttle return spring, Air Cleaner, Intake Manifold, Distributor, ignition wires, coil, spark plugs, fuel Pump, Fuel Lines, Pulleys with the Alternator, Power Steering or A/C compressor. Its important to make an apples to apples comparison.

3. Does your engine look any different from any different from anybody elses?

When you pop open the hood having an engine that has been tailored to your needs is a great feature. TD Global Engines offers our engines in a range of different engine block colors, ignition wire colors, pulley kit options and polished packages. This isnt easy selling a customized crate motor but we know it really makes a difference to our customers.

4. Do they really know about engines?

Often times when speaking to a salesman over the phone you’ll get a price and then often a reply Do you want the engine or not? Thats it!! TD Global Performance deals solely with Engines so we dont try to be everything to everybody. With thousands of engines produced and sold over the years, we’ll work with you to find the right engine combo, ask the right questions and offer suggestions. We’ll spend the time to go in detail on what you’ll get, not get and guidelines for an easier installation. Put our 40 years of experience to work!! Unfortunately personalized attention is considered more of a luxury to most companies these days.

5. Are you buying Horsepower or Heartache?

We’ve read our share of articles in a Hot Rod Magazine about a 1500 Horsepower Supercharged Twin Turbo engine hooked up with a bottle of nitrous. For all intensive purposes these cars are useless for a daily driver. Be cautious of the lure for big Horsepower and Torque numbers. It can look impressive on a piece of paper but when your spending more time under the hood rather than actually behind the wheel it loses its appeal fast! The fact of the matter is Low end power out of your car or truck is more important than what the horsepower numbers are @ 6000 RPMs. We setup most of our engines to achieve its torque & HP to kick in below the 4000 RPM range so you experience the power without mashing the throttle to 100 mph. Our objective is to provide an engine that is easy to install, fun to drive, responsive to the throttle and deliver years of driving pleasure.

6. Is the Engine Live Run Tested under Real World Conditions for 45 Minutes?

Most engines may be spin tested for Oil pressure but that’s about it. When you buy an engine each Ready to Run engine purchased from us is Hot run tested. Checked for Oil pressure, vacuum problems, coolant leaks, Fuel leaks, Timing is Setup, Fuel Mixtures, Idle and another 25 other steps involved. Ask before your Purchase, It’s your Money, Why take a chance? We have revolutionized the Crate Engine Industry and continue to do so.

Technical Help FAQs

If the lifting points are Accessible, pickup diagonally from the front Left or Right Front Cylinder Head to the Rear Left or Right Cylinder Head. Otherwise from exhaust port holes in the cylinder Heads. Use a high grade Bolt that does not stick out more than a ½ inch otherwise it will bend up and snap off from the chain or cable causing the engine to fall . USE a heavy duty chain or cable long enough to prevent scratching the Valve covers or damaging the Air Cleaner. Never stand under an engine that is suspended in the air, always ask yourself if it falls where will I be.

We normally suggest using a high Grade SAE 10W/30 Motor oil along with a ½ pint of a good quality zinc break in oil. After 2 oil changes if you would like to go with a synthetic or blended version then this is O.K. Do an initial oil change after 500 Miles then just every 3000 miles from there. Note on the first oil change your oil will look blacker than normal this is because when we assemble the engine we use a heavy duty Graphite on all Moving parts. Many people will ask how many quarts of oil does my engine hold. We have to tell you that every engine is a little different because we install the oil pan that is Made for the application, many will only take 4 quarts and some as many as 8 quarts. Here is how we want you to do it, on initial oil and filter change, first fill the new oil filter to the top, Then install 3 quarts of oil in the engine, then count how many additional quarts does it take to reach the full mark on the Dipstick, caution do not overfill.

We will normally do the break in of the camshaft on our Turnkey engines. Upon taking your vehicle on the road for the first time stagger the throttle from 30 to 50 MPH several times to get the Piston Rings seated properly. Keep the RPMs under 4000 RPMs for the first 1000 miles.

Keep them under 5800 RPMs. The power starts to drop above this anyway in most Street Engines. You will have all the power you’ll ever need below this level anyway. Going beyond this definitely increases your chances of damaging internal Parts.

When filling cooling system, top off of Antifreeze and Water with engine cold. After engine is started check coolant Level after engine reaches 160 F. Top off as necessary. Always use caution around hot coolant, Always use a temperature gauge not an idiot light. After the engine reaches 180 degrees shut it down and let the engine cool down then slowly remove the radiator cap start the engine and top off.

Clean Off the timing pointer.

- Clean off the Balancer we usually mark 15 and 34 degrees on it.

- Warm up engine.

- Hook up your timing light.

- Pull vacuum line off the distributor vacuum advance.

- Bring RPM’s up to 3,000 and hold steady.

- The Mark on your timing pointer should line up with the 34 degree mark on the Balancer.

- Adjust if necessary.

- Hook up the vacuum advance hose, timing will be correct at all rpm’s.

- We hook up the vacuum advance this way because it helps to give a much better throttle response and a better idle.

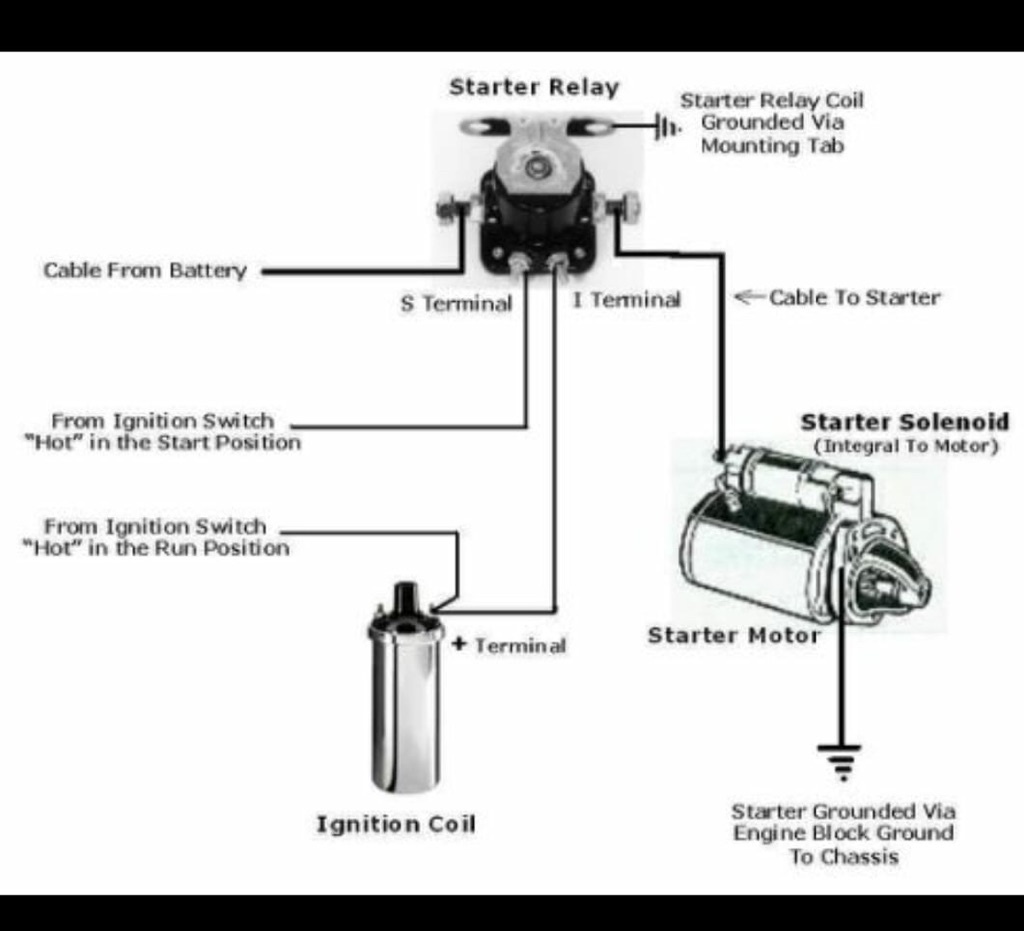

Your Electronic small body Distributor will have 3 wires coming out of it:

- Red goes to Positive on the Coil

- Orange wire goes to Negative on the Coil

- Black goes to Ground.

You need 12 Volts Coming from your Ignition switch, both Crank and run position, that works on and off with the Key.

Also, a word of warning, never hook up an electric fan on the same wire that powers your distributor, it must be on a separate circuit coming from your fuse box. Here is what can happen if you shut off the engine and fan is still spinning it acts like a generator and sends a voltage spike back to your Distributor and it can burn out the module in the distributor giving you a no spark condition.

The CSI ( Charging Circuit Integrated ) alternators that we use are 140 Amp, They are used around the world. they only require a 6 gauge wire from the Alternator to the Positive terminal on Your Battery, no other wires or plugs should be used. There are so many Aftermarket wire harnesses’ out there most of them are universal Harnesses, they should not be hooked up to a ( one wire Alternator ) These CSI Alternator systems are Isolated and work on their own.

Just run a 6 gauge wire from the terminal with the nut on the alternator to the positive Battery terminal the engine will start and charge the Battery at 14.2 volts. you will need to hook up a separate voltmeter under your dash to monitor your charging system.

You should also be sure when they installed your engine, that your engine must have a 4 gauge heavy duty ground wire from the engine block to the vehicles frame.

GM HEI wiring terminals

Here are the part Numbers you can order from www.summitracing.com although most auto parts store will also have them many different brands >>>> be sure to tell the guys the Power lead must be hooked up to the Ignition terminal so that the distributor has 12 volts with the key on and no voltage with the key off. Never hook up to the same wire that powers an electric fan or the automatic choke

Painless Wiring 30809 – Painless Performance HEI Power Pigtails

Compare

HEI Power Pigtail, GM HEI Distributors, Each

Part Number: PRF-30809

Painless Wiring 30813 – Painless Performance HEI Tachometer Lead Pigtails

Compare

Wiring Harness, HEI Tachometer Lead, 6 ft. Length, Each

Part Number: PRF-30813

Very important to follow these instructions:

Distributor and Electric Choke positive terminals must be hooked up to separate 12 volt key controlled (on and off with key ) If you use an electric fan it must be hooked up to a separate circuit otherwise it can burn out the ignition module in the distributor. Here is why if you shut the vehicle off and the fan is still spinning the fan acts like a generator and sends back a voltage spike that instantly burns out the Ignition Module in the distributor.

Also be sure to have a heavy duty 4 Gauge Ground cable going from the engine block to the vehicle frame otherwise you will constantly be adding water to your battery and your alternator will be spiking voltage at 18 volts.

Most auto parts stores have a simple piece that plugs into your fuse panel and adds 4 separate key controlled circuits that plugs into the accessory circuit.

In about 90 % of the cases it usually comes down to two issues, It can be the choke is Binding or it has not been wired correctly, the electric choke must have 12 volts whenever the engine is running. Start with the engine cold overnight, push the gas pedal to half throttle to set the choke it should snap shut, now let’s remove the air cleaner Lid only, look to see that choke butterfly is now closed, check to see if it is opening and closing smoothly by pushing the top butterfly open and closed with your finger it should open and close easily without any binding, sometimes we have to use a plastic spacer for the Air cleaner to clear the Distributor they are very touchy if they are not put back on correctly they will bind up the choke mechanism, now start the Vehicle it should go on fast idle and the choke will start to open fully after about 10 minutes of running, If not have a certified mechanic check and repair as necessary.

Another more serious problem is you Have picked up a piece of dirt Or rust in the Carburetor Needle and seats which cause the carb to dump raw gas into the intake, if you have an old fuel tank 10 Years or older by now over the years the tank has collected small amounts of water which turns to rust, water is heavier than fuel so the water and rust settles to the bottom of the tank and is pumped into your Carb or fuel injectors causing a Major flooding problem. If that is the case you will have to have a professional remove the carb and have the needle and seats cleaned by a professional Carb person, or in the case of fuel injectors those would have to be replaced. Engine Factory always recommends replacing a gas tank that is 10 years or older, go online Holley has a good selection of new fuel Tanks

Over the years One question that get asked very often How do I know if I have installed my automatic Trans Torque converter Properly?

Now let me say this We are engine Builders Not Transmission builders But over the Years of building our own Cars we learned the right way and the wrong way about installing torque converters on a freshly Built Transmissions, we have found the following Method has always worked well for us.

The first thing Be sure when you order the Torque Converter tell the trans person what Camshaft and Horsepower you have. Are you building a cruiser or Hot street machine because this will determine what stall speed you want for the converter, Most cruisers will stay with a 2,000 stall speed, 400 HP around 2,500, 500 HP & Up will go with 2800 Stall Speed of course if you know your rear end ratio also give that to Transmission shop.

Now when you order your torque converter best to order the converter that has multiple bolt holes where the converter mounts to the engine flexplate, most performance converters normally have the multiple bolt holes.

Ok now when you’re ready to put the converter onto the Trans we always recommend take a look down in the converter and see if you see any trans fluid pour in 1 quart It is best so that it has some lubrication and helps to pick up the pressure faster, now look at the front seal if it looks ok then spread a little of trans fluid on the converter shaft just so the seal has instant lubrication so you don’t burn the seal lips. Now pick up the converter and slide over the trans splined shafts, slowly push into the Transmission and keep rotating the converter you will see it drop back a little that shows it went onto the 1st set of splines now keep turning and pushing back it will then drop back one more time and that means you have dropped back on the second set of splines and have engaged into the Transmission front pump give the converter a spin there should be a nice smooth spin no binding or noise.

Now it is time to mate the Transmission to the Back of your engine, first make sure the Pins that the Transmission line up on don’t have any paint on them, also make sure that the Transmission alignment holes are nice and clean. Now take a couple of Extra 3 inch long bolts and cut the heads off, just thread them into the back of the engine by hand about 3 full turns this will help you to easily slide the trans onto the back of the engine, now have your trans bolts ready to install thread them in by hand and use a hand ratchet, you will now see that the face of the trans and the block are mated together. Now very important reach under and try to spin the torque converter, If you can that means success you now know the Torque converter is installed in the trans correctly, so now is the time to install your converter to flexplate Bolts, you should have about ¼ of an inch space between converter and flexplate that’s perfect, now pull the converter forward until it lines up flush with the flexplate, now install your torque converter bolts nuts and lock washers and torque up everything, now Ford converter use the same procedure except the ford converter have studs that you have to spin the converter to line up the holes into the flexplate. Always be sure you use a new Trans cooler.

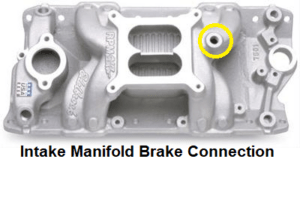

The image above shows where you hook up power brakes.

you will need these fittings Edelbrock Number 8096 and Edelman # 846260 Order both from

www.summitracing.com There are many other places on the Carb, look at 2nd attachment.

to hook up a vacuum hose going down to the Transmission it needs Vacuum all the time.

These items should be left to a certified mechanic.

On some engines Like Corvettes and Cobras The customer fills his cooling system and thinks his engine is full it is not; that is because the radiator fill neck sits lower than the Thermostat housing, Coolant does not run up hill which means the upper portion of your intake system is not completely full and that is where your Temperature sender sits. Here is an “Ultra Thermostat Housing” that resolves this.

Now another reason if your engine temperature is higher than normal; If you have installed a late model Serpentine Belt system that is driven by a single belt, You must be aware that those system use reverse turn water pumps. Here is where most people go wrong they put on a fan and fan clutch that is for a standard rotation pump, this means your Fan is now turning the wrong way, easiest way to resolve this issue is to use an electric fan we recommend the Flex lite 180 series they deliver 3300 Cfm’s of air flow and will keep your engine cool.

Over the years we have found out that valve tapping is misdiagnosed 90 % of the time the header gaskets shrink up and give you that typewriter sound so please read below and check closely. Also if a vehicle isn’t driven on a daily basis moisture collects in the valve lifters and the plungers in the lifters will stick because rust forms on the them. Best to change oil and filter and take the vehicle for a good ride and see if it gets better, if it does then start putting some miles on it weekly. Try to stay away from gas that has an Ethanol blend it is terrible for classic vehicles because it collects moisture.

Engine sounds like a valve tap but it could Be a Header Gasket leaking.

Here is what usually happens after about 500 miles the header gaskets shrinks up and starts to leak especially when the vehicle is cold. Easiest way to diagnose a Header gasket leak is to get a big bath towel start the engine up cold and hold the towel over the area that you hear the noise coming from if the noise changes then most likely it is the Header gasket leaking. You can try to retorque the header bolts to 30 ft. lbs. and if they keep loosening up use # 271 Loctite on the bolts. If the gasket has burnt through then new gaskets are probably necessary.

Your Holley Sniper engine has been live run and properly set up, only use below if you think someone has changed the settings.

- Follow prompts on initial set up screen usually set idle setting around 1020 rpm. on menu screen.

- Start up engine and let idle until coolant temperature must reach 160 F. Set idle screw to 1000 rpm if needed for setting timing.

- Then set your distributor timing so at 3000 rpm with vacuum advance hose disconnected from distributor. Set timing to 34 degrees BTDC. Then hook the vacuum advance hose back into distributor.

- Now shut engine off & turn throttle body idle screw clockwise one full turn .

- Then start engine up idle will be at 2000 rpm.

- Then very slowly turn idle screw counterclockwise to the left. Until on the menu screen the IAC % reading is reading between 2% & 5% . Then let engine idle for a minute so computer can learn.

- Then restart engine and engine idle should Level off to the setting you set it at from step one. Which was about 1020 Rpm. That’s it.

The EFI system we will be

Using is the Holley Sniper # 550-511 we will have the hand held all dialed in to use this system. Note we do not supply ( fuel tanks or in tank pumps ) you can purchase direct from our sister site TDmotion.com

This in-tank fuel pump module is a high-pressure unit that flows 255 liters per hour (LPH) and is capable of supporting electronic fuel injection (EFI) engines producing up to 550 horsepower • A pre-calibrated fuel-level sending unit designed to work with the factory fuel gauge for this application is included • This module also features a Hydra Mat filter which has a unique internal reservoir that keeps fuel available at the pick-up and also provides protection from contaminates Fuel pressure is internally regulated to 58 psi eliminating the added expense and effort of purchasing and installing an external fuel pressure regulator – no separate return line is required because this module returns excess fuel right inside the tank! This 1964-70 Mustang Muscle Car EFI Fuel Pump module was designed as a direct replacement for your factory pick-up and sending unit. There is no need to purchase a custom EFI fuel tank. You can even retain the factory fuel hard line – just connect the outlet of the pump module to the hard line on your vehicle with EFI-rated fuel hose and hose clamps available in the Earls Vapor Guard line. This Muscle Car EFI Module includes a 255 LPH fuel pump and a Holley Hydra Mat. Hydra Mat is an amazing patent-pending fuel reservoir system that reduces fuel starvation issues that might otherwise occur while cornering, accelerating, stopping, traversing inclines, and during low fuel conditions. This new kit has all of the extra components to fit all three sizes of Mustang fuel tanks from 1964-1970. You choose which fuel gauge float arm for your factory fuel tank size! Fitment:

HOLLEY 255 LPH OE STYLE EFI FUEL TANK MODULES

1964-1970 Mustang;

Product Type

– Fuel Pump Module

PART# 12-305

Info before you switch from a Carb to an EFI engine system. Here is the problem YOUR Camshaft may not EFI compatible, yes switching over to EFI sounds Good, but with Camshaft that is in your engine you will find it difficult to Tune, In other words you would have a hard time to get the engine to run smooth, Sniper EFI systems require a camshaft that has a 112-114 lobe separation in most cases.

This can be a huge list but one of the most important ones to mention would be the Radiator. Use a brand new Aluminum or 3 to 4 core Radiator to keep your replacement engine cool. Some other items would include Engine and Transmission Mounts, Clutch, Torque converter, Fan, belts, hoses, U-Joints, pulleys, hoses and clamps, fuel lines, sensors etc. Reference our installation tips list along with and review each tag on the engine. If you don’t feel comfortable to take this on then contact a qualified mechanic. Early model vehicles with drum brakes should be converted to disc brakes when installing a high performance engine. Most serpentine system require using an electric Fan the Flex lite 180 series puts out 3300 cfm and will keep your engine nice and cool.

Occasionally we have a customer call saying on his Serpentine system it leaves no room to install an electric fan. I have seen it before on certain applications sometimes if you have installed a 4 core radiator it is to wide leaving no room, www.proformparts.com has slim fit electric fans. if that won’t work Here is the easiest fix. forget about the electric fan and install a Flex Fan it only needs less than 2 inches of clearance. note fans are available in standard or reverse rotation You must First determine which direction your water pump is turning either clockwise, or counter clockwise, Flex Fans can be ordered from www.summitracing.com To install the Flex fan remove the 4 Allen screws and the chrome nose cover from the front of the water pump, install the new Flex fan with correct length bolts with flat and lock washers this will give you the clearance you need. Check all clearances before starting engine.

If your engine installation looks like it will be more than 6 months it is best to prep your engine to Help prevent problems down the road, the first issue you should know when the engine block sits for a long time the block will start to rust out inside and it will continue to eat away at the casting and water pump, when the engine is first started this rust will pump into your new radiator and cooling system, Here is the best way to prevent that, Have 2 gallons of a good brand of antifreeze and 1 quart of rust Preventative, Clamp on a 2 foot long Radiator hose on the large inlet on your water pump, Have a clamp ready to install on the other end of the 2 foot hose, Block off any heater hose fittings, now hold up the Hose and slowly pour in 2 gallons of antifreeze and rust preventative into the block, when the hose fills up, slip the hose onto the upper thermostat housing and clamp off, your cooling system will be protected.

If possible do the following below.

Top off Oil with a good quality Brand SAE 10W 30 oil fill until the dip stick says full, disconnect Power wire at Distributor, Remove the Air Cleaner, Open the Throttle and spray down In the CARB a 5 second shot of WD 40 then spin the engine over for 20 seconds, let it sit for 5 minutes, then spray in another 5 second shot of WD, spin the engine over again, for about 20 seconds this time keep an eye on the oil pressure you should see it starting to come up. Now hook up power to your distributor, install the air cleaner, Now when you are ready to start your engine be sure there is fresh fuel in the gas tank, start the engine it should fire up run it on fast idle about 2,000 rpms IMPORTANT Monitor the oil pressure it should come up immediately. I am sure if it had oil pressure when it was stored away no reason it wouldn’t have it now, top off cooling system and monitor temp and then road test.

Chevy Flywheels and starters compatibility

Flywheel and starter on the left is 153 tooth and the compatible starter has bolt pattern straight across from each other; this flywheel uses a 10.5 inch Clutch; Starter can be ordered from www.summitracing.com Search Item PowerMaster PWM-3631

Flywheel and starter on the right is 168 tooth and the compatible starter has the bolts staggered across from each other; this flywheel uses a 11 inch clutch. Starter can be ordered from www.summitracing.com Search Item PowerMaster PWM-3510

See important technical item below.

The starter bolts are special and also the engine block is special where the starter bolts seat >>> When you get your starter off always look at how the engine block has the starter bolt holes recessed up in the block again the threads in the block should be recessed up in the block about 3/8 of an engine this allows the shoulder that is built on the starter bolts to fit up in that recess precisely that is what gives the bolts the strength and keeps everything in perfect alignment.

Chevy flexplate and starter compatibility: both have Balance weights 86-96 when they bolt up be sure weight goes to the front of the engine.

Also, years that have these combos please consider that over the years Chevy engines have been transplanted into just about every combination out there. A quick way to tell what size flywheel you have is to look closely at starter bolt configuration and compare to my illustrations.

Flexplate and starter on the left is 153 tooth and the compatible starter has bolt pattern straight across from each other.

– This starter is a DB Electric Brand part Number SDR0059 you can order direct from Amazon

Flexplate and starter on the right is 168 tooth and the compatible starter has the bolts staggered across from each other.

– This starter is a DB Electric Brand Part Number SDR0031-L buy Direct from Amazon.

See important technical item below:

Camaros

68-83 Camaros had 168 tooth flywheels

84-93 Camaros had 153 tooth flywheels.

Corvettes

67 and earlier Corvettes had 153 tooth flywheels.

68-83 Corvettes had 168 tooth flywheels

84-93 Corvettes had 153 tooth flywheels

If a customer’s torque converter does not bolt up to flexplate then they will need the torque converter that has multiple bolt holes.

The starter bolts are special and also the engine block is special where the starter bolts seat >>> When you get your starter off always look at how the engine block has the starter bolt holes recessed up in the block again the threads in the block should be recessed up in the block about 3/8 of an engine this allows the shoulder that is built on the starter bolts to fit up in that recess precisely that is what gives the bolts the strength and keeps everything in perfect alignment.

Small Block Chevy Torque spec’s read carefully

| Bolt size and Location | Lube or Sealer | Torque to: |

| 7/16 Main Caps (2 bolt) | Engine Oil | 70 ft-lbs. |

| 7/16 Inner Main Caps (4 bolt) | Engine Oil | 70 ft-lbs. |

| 7/16 Outer Main Caps (4 bolt) | Engine Oil | 65 ft-lbs. |

| 3/8 Outer Main Caps (4 bolt) | Engine Oil | 40 ft-lbs. |

| 3/8 Connecting Rod | Engine Oil | 45 ft-lbs. |

| 11/32 Connecting Rod | Engine Oil | 45 ft-lbs. |

| Cylinder Heads | Engine oil (blind hole) Sealer (water jacket) | 65 ft-lbs. |

| Rocker Studs (screw-in) | Engine Oil | 50 ft-lbs. |

| Oil Pump | Engine Oil | 65 ft-lbs. |

| Oil Pan | Engine Oil | 12 ft-lbs. |

| Cam Sprocket (upper gear) | Thread Locker | 20 ft-lbs. |

| Timing Cover | Engine Oil | 6 ft-lbs. |

| Intake Manifold (Cast Iron Heads) | Non- Hardening Sealer | 30 ft-lbs. |

| Valve Cover | Engine Oil | 3 ft-lbs. |

| Exhaust Manifold | Anti-Seize Lubricant | 25 ft-lbs. |

| Spark Plugs | No Lube or Sealer | 20 ft-lbs. |

| Flexplate (Automatic) Flywheel (Clutch) | Thread Locker | 60 ft-lbs. |

| Clutch Pressure Plate | Thread Locker | 35 ft-lbs. |

| Centerbolt (Harmonic Damper) | Engine Oil | 60 ft-lbs. |

| Bellhousing (Transmission to Block) | Engine Oil | 25 ft-lbs. |

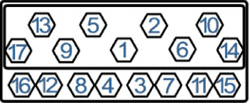

SBC Cylinder Head Bolt Tightening Sequence

Ford Torque specs read carefully

Ford 260, 289, 302 (5.0L) Verify These specs they may not be your engine specs check a service manual for your year and model.

Always torque bolts in three equal increments

| Bolts or Parts | Lube or Sealer | Torque to: |

| Main Caps | Engine Oil | 70 ft-lbs. |

| Outer Main Cap Bolts | Engine | 40 ft-lbs. |

| Connecting Rod 260, 289, 302 *289HP and Boss 302 | Engine Oil | 25 ft-lbs. *45 ft-lbs. |

| Cylinder Heads | Engine oil (blind hole) Sealer (water jacket) | 70 ft-lbs. |

| Rocker Arms | Engine Oil | 20 ft-lbs. |

| Oil Pump | Engine Oil | 25 ft-lbs. |

| Oil Pan | Engine Oil | 15 ft-lbs. |

| Camshaft Thrust Plate | Thread Locker | 10 ft-lbs. |

| Cam Bolt (upper gear) | Thread Locker | 40 ft-lbs. |

| Front Cover | Engine Oil | 20 ft-lbs. |

| Intake Manifold (Cast Iron Heads) | Non- Hardening Sealer | 25 ft-lbs. |

| Valve Cover | Engine Oil | 10 ft-lbs. |

| Flexplate (Automatic) Flywheel (Clutch) | Thread Locker | 85 ft-lbs. |

| Clutch Pressure Plate | Thread Locker | 25 ft-lbs. |

| Centerbolt (Harmonic Damper) | Thread Locker | 90 ft-lbs. |

| Bellhousing (Transmission to Block) | Engine Oil | 25 ft-lbs. |

Power steering & AC line kits Available at www.gottashow.com

A universal Power Steering Line Kit for High Pressure and Low Pressure

Note: Some kits will require custom AC & PS lines the company above will assist you on these items.

A.C. Compressor: Sandon Compressor accepts R134A Refrigerant.

NOTE COMPRESSOR HAS OIL IN IT

Note: if the fitting on back of our PS pump is not compatible with your PS pressure line, the fittings on back of both PS pumps will interchange, Just switch the fittings they just thread out. Order a new PS pressure line for a 1971 Chevy impala that will work with our pump.